A barrel of crude oil has a mixture of all sorts of hydrocarbons in it.

Oil refining separates everything into useful substances

Chemists use the following steps:

1. The oldest and most common way to separate things into various components (called fractions), is to do it using the differences in boiling temperature. This process is called fractional distillation. You basically heat crude oil up, let it vaporize and then condense the vapor.

2. Newer techniques use Chemical processing on some of the fractions to make others, in a process called conversion. Chemical processing, for example, can break longer chains into shorter ones. This allows a refinery to turn diesel fuel into gasoline depending on the demand for gasoline.

3. Refineries must treat the fractions to remove impurities.

4. Refineries combine the various fractions (processed, unprocessed) into mixtures to make desired products.

For example, different mixtures of chains can create gasolines with different octane ratings,

The products are stored on-site until they can be delivered to various markets such as gas stations, airports and chemical plants.

In addition to making the oil-based products, refineries must also treat the wastes involved in the processes to minimize air and water pollution.

Fractional Distillation

The various components of crude oil have different sizes, weights and boiling temperatures; so, the first step is to separate these components.

Because they have different boiling temperatures, they can be separated easily by a process called fractional distillation.

The steps of fractional distillation are as follows:

1. You heat the mixture of two or more substances (liquids) with different boiling points to a high temperature. Heating is usually done with high pressure steam to temperatures of about 1112 degrees Fahrenheit / 600 degrees Celsius.

2. The mixture boils, forming vapor (gases); most substances go into the vapor phase.

3. The vapor enters the bottom of a long column (fractional distillation column) that is filled with trays or plates.

The trays have many holes or bubble caps (like a loosened cap on a soda bottle) in them to allow the vapor to pass through.

The trays increase the contact time between the vapor and the liquids in the column.

The trays help to collect liquids that form at various heights in the column.

There is a temperature difference across the column (hot at the bottom, cool at the top).

4. The vapor rises in the column.

5. As the vapor rises through the trays in the column, it cools.

6. When a substance in the vapor reaches a height where the temperature of the column is equal to that substance's boiling point, it will condense to form a liquid. (The substance with the lowest boiling point will condense at the highest point in the column; substances with higher boiling points will condense lower in the column.).

7. The trays collect the various liquid fractions.

8. The collected liquid fractions may:

pass to condensers, which cool them further, and then go to storage tanks

go to other areas for further chemical processing

Fractional distillation is useful for separating a mixture of substances with narrow differences in boiling points, and is the most important step in the refining process.

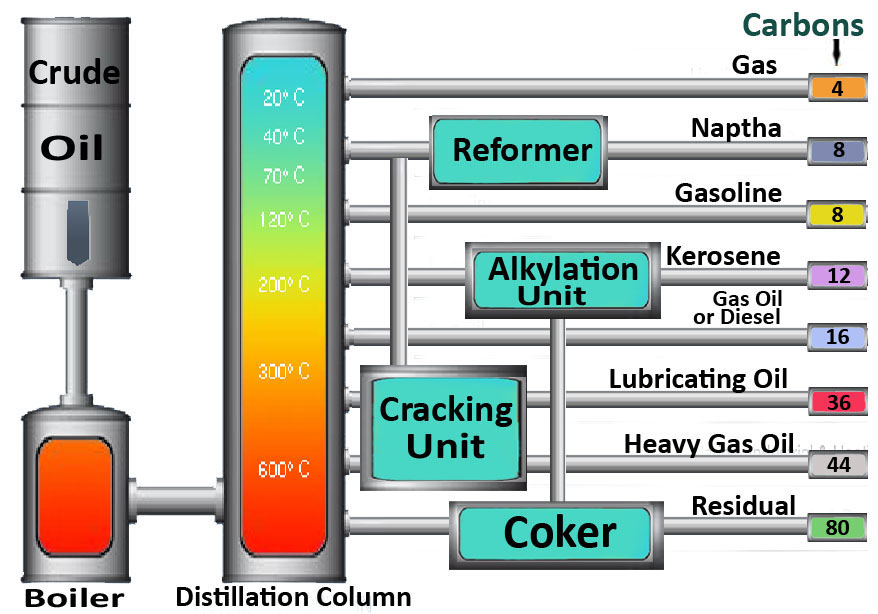

The oil refining process starts with a fractional distillation column.

On the diagram, you can see several chemical processors that are described in the next section.

Very few of the components come out of the fractional distillation column ready for market

.

Many of them must be chemically processed to make other fractions.

For example, only 40% of distilled crude oil is gasoline; however, gasoline is one of the major products made by oil companies.

Rather than continually distilling large quantities of crude oil, oil companies chemically process some other fractions from the distillation column to make gasoline; this processing increases the yield of gasoline from each barrel of crude oil.

Chemical Processing

You can change one fraction into another by one of three methods:

breaking large hydrocarbons into smaller pieces (cracking)

combining smaller pieces to make larger ones (unification)

rearranging various pieces to make desired hydrocarbons (alteration)

Cracking

Cracking takes large hydrocarbons and breaks them into smaller ones.

There are several types of cracking:

Thermal - you heat large hydrocarbons at high temperatures (sometimes high pressures as well) until they break apart.

• steam - high temperature steam (1500 degrees Fahrenheit / 816 degrees Celsius) is used to break ethane, butane and naptha into ethylene and benzene, which are used to manufacture chemicals.

• visbreaking - residual from the distillation tower is heated (900 degrees Fahrenheit / 482 degrees Celsius), cooled with gas oil and rapidly burned (flashed) in a distillation tower. This process reduces the viscosity of heavy weight oils and produces tar.

• coking - residual from the distillation tower is heated to temperatures above 900 degrees Fahrenheit / 482 degrees Celsius until it cracks into heavy oil, gasoline and naphtha.

When the process is done, a heavy, almost pure carbon residue is left (coke); the coke is cleaned from the cokers and sold.

Catalytic - uses a catalyst to speed up the cracking reaction. Catalysts include zeolite, aluminum hydrosilicate, bauxite and silica-alumina.

• fluid catalytic cracking - a hot, fluid catalyst (1000 degrees Fahrenheit / 538 degrees Celsius) cracks heavy gas oil into diesel oils and gasoline.

• hydrocracking - similar to fluid catalytic cracking, but uses a different catalyst, lower temperatures, higher pressure, and hydrogen gas. It takes heavy oil and cracks it into gasoline and kerosene (jet fuel).

After various hydrocarbons are cracked into smaller hydrocarbons, the products go through another fractional distillation column to separate them.

Unification

Sometimes, you need to combine smaller hydrocarbons to make larger ones -- this process is called unification. The major unification process is called catalytic reforming and uses a catalyst (platinum, platinum-rhenium mix) to combine low weight naphtha into aromatics, which are used in making chemicals and in blending gasoline.

A significant by-product of this reaction is hydrogen gas, which is then either used for hydrocracking or sold.

Alteration

Sometimes, the structures of molecules in one fraction are rearranged to produce another. Commonly, this is done using a process called alkylation. In alkylation, low molecular weight compounds, such as propylene and butylene, are mixed in the presence of a catalyst such as hydrofluoric acid or sulfuric acid (a by-product from removing impurities from many oil products).

The products of alkylation are high octane hydrocarbons, which are used in gasoline blends to reduce knocking.

Treating and Blending the Fractions

Distillated and chemically processed fractions are treated to remove impurities, such as organic compounds containing sulfur, nitrogen, oxygen, water, dissolved metals and inorganic salts.

Treating is usually done by passing the fractions through the following:

a column of sulfuric acid - removes unsaturated hydrocarbons (those with carbon-carbon double-bonds), nitrogen compounds, oxygen compounds and residual solids (tars, asphalt)

an absorption column filled with drying agents to remove water

sulfur treatment and hydrogen-sulfide scrubbers to remove sulfur and sulfur compounds

After the fractions have been treated, they are cooled and then blended together to make various products, such as:

gasoline of various grades, with or without additives

lubricating oils of various weights and grades (e.g. 10W-40, 5W-30)

kerosene of various various grades

jet fuel

diesel fuel

heating oil

chemicals of various grades for making plastics and other polymers